Mold polishing is a critical process in many industries. The smooth and polished surface of the mold directly affects the quality, durability, and aesthetics of the produced parts. In this article, we will focus on the importance of mold polishing systems and their role in the industry.

There are many advantages to mold polishing:

Product Quality: A smooth mold means a better final product. Reducing errors in the production process makes quality control processes easier.

Aesthetic Appearance: The polishing process makes products more aesthetically pleasing. Especially in consumer products, appearance is a critical sales factor.

Durability: Well-polished molds are more resistant to wear and tear. This means long-lasting molds and products.

The mold polishing process generally consists of several stages:

Preparation: Cleaning and preparing the mold surface.

Cleaning: Molds must be cleaned before the polishing process. Dirt, oil, and other residues can reduce the effectiveness of the polishing process.

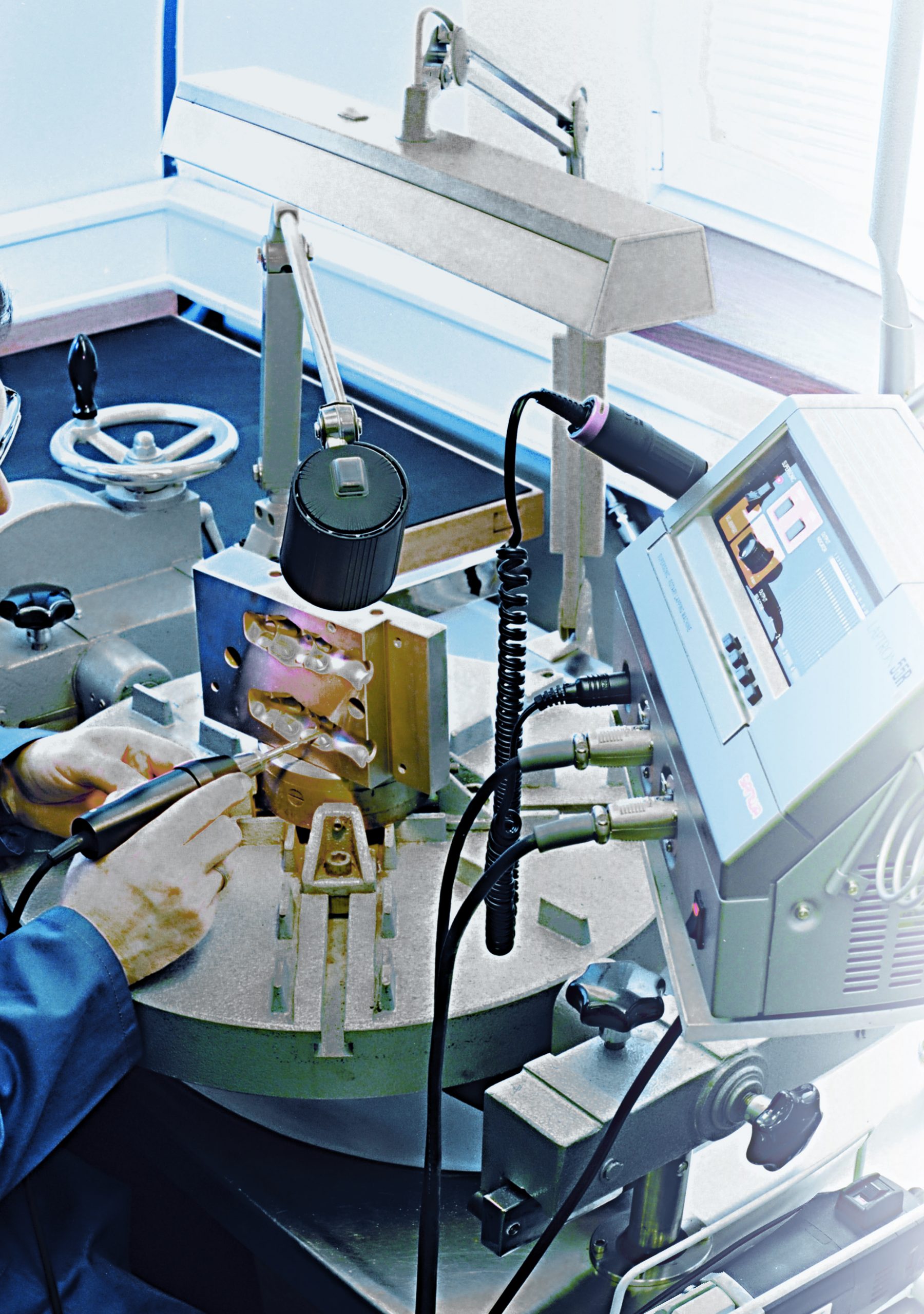

Mechanical Polishing: In this stage, the surface of the molds is smoothed using various sandpapers and polishing pastes.

Chemical Polishing: In some cases, a chemical polishing process can be applied. This process dissolves thin layers on the mold surface and provides a smooth surface.

Final Inspection: After the polishing process is completed, the molds are subjected to final inspections. Any errors or deficiencies are corrected.

Mold polishing plays a critical role in the production process and directly affects product quality, durability, and aesthetics. Using the right polishing systems increases efficiency in the production process and reduces costs. Therefore, investing in mold polishing systems can provide significant benefits in the long run.